What a Fluke! How Art, Science and Engineering saved a mans life!

A Dutch metro train was saved by a unique piece of urban art 10 meters into the air, after it derailed and crashed through some safety barriers in early November 2020. The train passed through a stop block at De Akkers Station in Spijkenisse, on the outskirts of Rotterdam, before it was saved by a blue whale tail sculpture! It is still unclear what may have caused the accident. The stunning artwork that saved a mans life is the result of science, art and engineering innovations.

The whale tail sculpture which stands 10 meters above the surrounding streets and water below managed to catch half of one of the metro carriages, became an unlikely temporary addition to the local art. Thankfully, the carriage was empty and no one was injured. The driver was able to get out of the train himself, however was transported to the nearest hospital as a precaution. He has since been arrested and was questioned by police. The train was later removed from the whale sculpture.

The Whale Tail Sculpture itself, is a feat of unique specialist Dutch engineering that has a compelling story all on its own. Nearly nineteen ago, three men, Eric van Uden, Hans Muller and Peter Globevnik completed the "Whale Tail" sculpture that sits at the end of the metro line in the suberbs of Rotterdam. The sculpture is made of hollow plastic only 6mm thick, yet somehow managed to hold a 20 ton train engine, constructed almost two decades ago.

As the sculpture was made with cutting edge engineering technology at the time, using an advanced manufacturing technique, which relied on composite materials and predictive modelling. The secret to this wondrous artwork's longevity, lay in that it is both lightweight, yet incredibly strong. The developers themselves lead interesting lives; Hans Muller who has a background in naval architecture founded Solico Engineering in 1989 and today runs the largest company of composite materials in the Netherlands with the help of his colleagues Peter and Eric. The company specialises in defence, maritime, architecture, automotive and other niche specific manufacturing and industrial sectors. Currently the Solico have on-going projects in tidal turbines and composite parts for yachts.

The Whale Tails were built with a specific function in mind, to assist with the strong winds typical of the coastal town in Rotterdam, although were inspired by local citizens of Skipjknesse who wanted artwork to mark the "tail" of the track of the newly completed transport system.

"The shape of the whale's flukes make the perfect wing. We knew that this could get a lot of wind force with the wind which presented us with an engineering challenge.", explained Peter Globenvik, the head of structural engineering behind the tails.

The engineers paid particular attention to the Eigen Frequency; a natural state of vibration of a structure, that if incorrectly calculated would lead to its collapse. In order to build the strong structure, Hans enlisted the help of an experienced biology artist who specialised in the creating scientifically accurate composite structures for zoos. Together the team worked on models design, ensuring to follow nature's proportions and the implementation of the design was tested using industrial scale 3D printing to test the whale tail's resilience in wind tunnels.

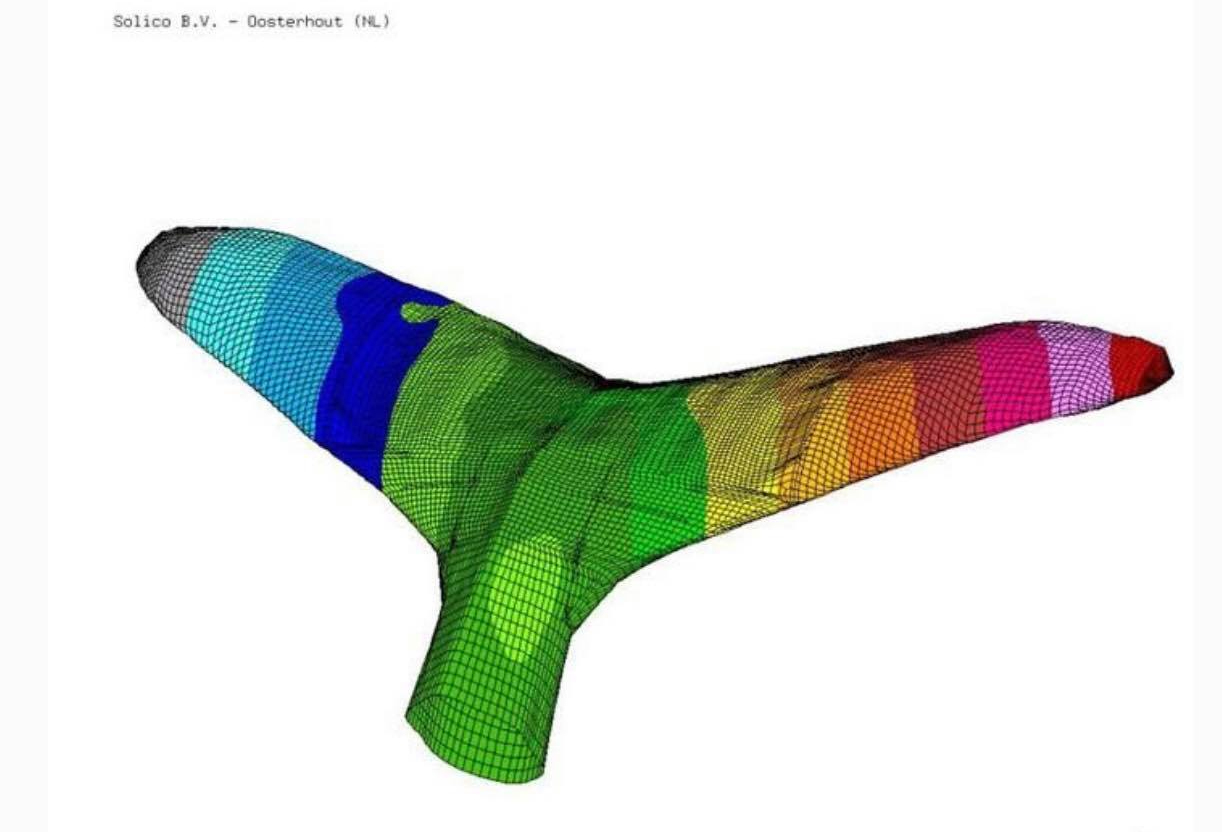

The tests were ran for vortexes, lift and air circulation as there had been vibration issues as a result of strong winds with other nearby projects. This allowed the engineers to develop a much stronger material based on the data collected using an advanced mathematical technique, called Finite Element Analysis, to digitally model the effects of the physical structure. These complex models allowed fewer physical prototypes to be built and relied on models of fluid dynamics, wave propagation and thermal analysis.

Once the designs were completed, they teamed up with Maropol, a production company that specialises in mouldings, to erect the final sculpture. One tail was created with a steel ladder and a composite skin, while the other without a steel structure. You may be surprised to know, that it was actually the one without the steel structure that was strong enough to hold the train carriage of the runaway metro train.

It was a combination of these advanced mathematical models, the 3D printing to allow for tunnel testing and the cutting edge additive composite material innovation, that has allowed the whale tails to be so robust and much more than just a stunning piece of artwork.

If you would like to know more about 3D printing and additive composite material in Ireland, visit UCC IGNITE start-up company Addaptiv's website or contact, Founder and CEO William Nolan.

SHARE THIS ARTICLE